Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

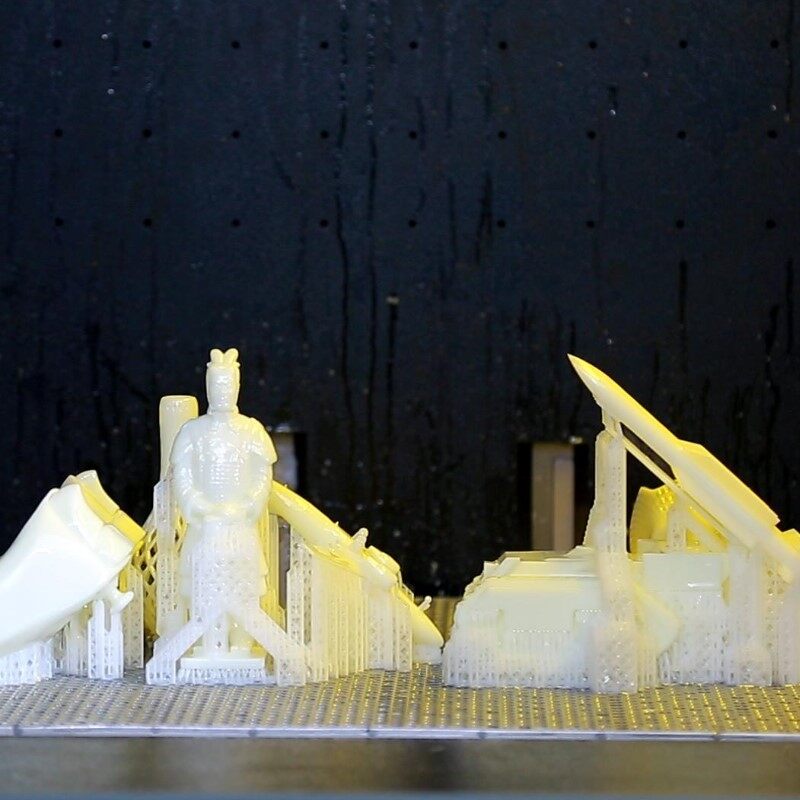

MJF 3D Printing Service

At Future Parts, we proudly offer Multi Jet Fusion (MJF) 3D printing services, utilizing HP’s groundbreaking technology. MJF is a powder bed fusion system, similar to SLS, that delivers exceptional results. Our MJF process utilizes PA (Nylon) material, which is known for its strength and durability, making it ideal for both prototyping and functional parts.

With MJF, we can produce high-quality prototypes and functional parts that meet the requirements of even the most demanding applications. The technology allows for intricate designs and complex geometries to be accurately reproduced, ensuring the final product matches your specifications.

In addition to its impressive performance, MJF offers versatility in terms of aesthetics. We offer both black and full-color versions, allowing you to choose the option that best suits your needs and enhances the visual appeal of your parts.

Specification

|

Maximum Build Size |

294 x 211 x 144 mm (11.6″ x 8.3″ x 5.7″) |

|

Lead Time |

3-4days |

|

Resolution |

± 0.3mm |

|

Prototyping Applications |

Functional, high-fidelity parts for testing |

|

End-Use Applications |

Low-volume, functional end use parts |

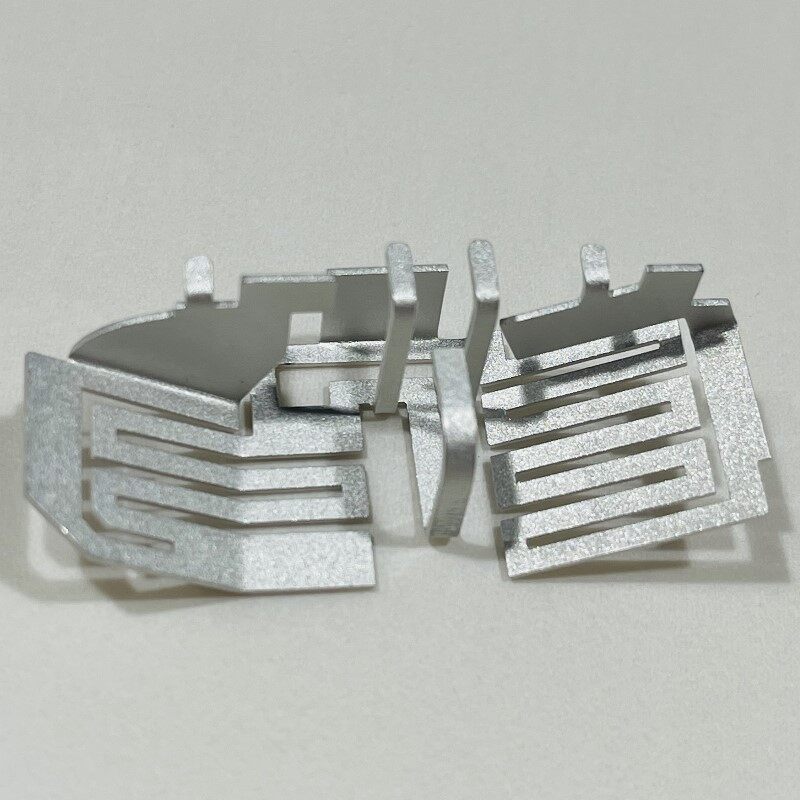

MJF Materials

MJF PA12 or Nylon 12 can withstand drastic temperature drops, even staying strong in below freezing periods. It is characterized by high strength, stiffness, strong resistance to cracking under stress, and an excellent long-term constant behavior.

Material Reference: PA12, PA12 Glass Beads

Appearance: Speckled Grey

Typical MJF Finishing Options

|

|

Applicable Materials |

Colour |

Description |

|

Sanding |

All |

_ |

Bead blasting is a standard MJF 3D printing finish used to remove any remaining powder from the printed parts. |

|

Dyeing |

All |

Black |

Dyeing is a fast and cost-effective way to colour MJF parts. It is mainly used to improve aesthetics. |

|

Dyeing |

All |

_ |

Vapour smoothing is used to enhance mechanical properties and a part’s colour consistency and hue. |

The Advantage of product

- Scalability

MJF 3D printing can make a single part or component as easily as dozens

or hundreds of production pieces.

- Complex Geometries

Geometries can be built more easily due to the 3D printing process,

adding complexity without additional cost.

- Rapid Turnaround

Parts can typically be shipped in 3-4 days, allowing for faster design

iterations and speed to market.

- Production Parts

MJF 3D Printing is capable of producing end-use parts with near-isotropic

properties on-demand, increasing throughput

The Application of product

Multi Jet Fusion produces functional nylon parts, great for testing and low-volume end-use.

The advantages of MJF make it applicable in many industries, including the automotive, aerospace, medical and electronics industries.

The Production Process of product

MJF builds parts by jetting a binding agent onto thin layers of polymer powder particles (typically nylon) and then sintering them using an IR heat source.